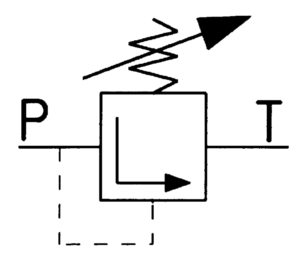

The overflow valves with thread connection are used for actuation type E: with adjustment screw.

The valves are suitable for use with lubricating and hydraulic oils and many other self-lubricating non-corrosive fluids. They deliver excellent heating oils EL, L, M, S and ES, coal tar oils and kerosene.

Material

casing of hydraulic cast iron (GGG 40); certificate on request; piston, valve tip, spring of hardened steel

Details

Summary:

hp-Overflow valve,

flow range: . . . . . (l/h)

pressure stage . . . . , adjustable . . . . . (bar)

Type: . . . . .

| Model | Possible pressure stages for each model |

Connection thread 2) | Flow range l/h |

Viscosity range >cSt |

Item No. |

| B – P – E / _ G 1/4″ 1) | 0 = 0,5 – 1,5 bar 1 = 1 – 4 bar 2 = 2 – 9 bar 3 = 6 – 25 bar 4 = 15 – 40 bar |

G 1/4″ | 6 – 120 | 2,8 bis 480 | 210000 |

| B – P – E / _ | G 3/8″ | 15 – 160 | 2,8 bis 480 | 210002 | |

| B – G – E / _ | G 1/2″ | 30 – 600 | 2,8 bis 480 | 210003 | |

| B – GH – E / _ 3) | G 3/4″ | 100 – 2000 | 2,8 bis 480 | 210004 | |

| B – GHG – E / _ | G 1″ | 300 – 6000 | 2,8 bis 480 | 210005 | |

| B – GHG – E / _ G 1 1/4″ | G 1 1/4″ | 500 – 10000 | 2,8 bis 480 | 210006 |

1) Not pressure stage 0

2) Pipe thread G…A DIN ISO 228-1

3) Not pressure stage 0, for pressure stage 1: 0.5 – 3.5 bar, all further pressure stages according to table

For very dirty heavy oils, the overflow valves may be fitted or retrofitted with a piston axial nut (heavy oil piston) at an additional cost.

| Model | Item No. | Ø for piston and hole |

| BP | 840750 | 20/2,5 |

| BG/FDR 15 | 840752 | 20/5,0 |

| BG/FDR 15 | 840754 | 20/7,5 |

| BGH/FDR 20 | 840756 | 30/10 |

| BGHG 1“/FDR 25 | 840758 | 35/15 |

| BGHG 11/4“/FDR 32 | 840760 | 35/25 |

| FDR 50 | 840762 | 50/30 |

| Model | a | b1 | c1 | d1 | d2 | f1 | max. Pipe | NW | f2 | Adjustment path h at pressure stage | |||

| 0 + 1 | 2 | 3 | 4 | ||||||||||

| P – 1/4″ | 55 | 65 | 37 | 36 | 52 | G 1/4″ | 10 x 1 | 8 | G 1/8″ | 15 | 12 | 8 | 7 |

| P | 55 | 65 | 37 | 36 | 52 | G 3/8″ | 12 x 1 | 10 | G 1/8″ | 15 | 12 | 8 | 7 |

| G | 55 | 65 | 37 | 36 | 52 | G 1/2″ | 18 x 1,5 | 15 | G 1/8″ | 15 | 12 | 8 | 7 |

| GH | 63 | 65 | 43 | 50 | 70 | G 3/4″ | 22 x 1,5 | 20 | G 1/4″ | 15 | 10 | 8 | 5 |

| GHG | 80 | 62,5 | 56 | 56 | 86 | G 1″ | 28 x 1,5 | 25 | G 1/4″ | 20 | 17 | 9 | 6 |

| GHG – 1 1/4″ | 80 | 62,5 | 56 | 56 | 86 | G 1 1/4″ | 35 x 2 | 30 | G 1/4″ | 20 | 17 | 9 | 6 |

For installation, operation and maintenance, follow the operating instructions that come with each piece of equipment.

Need additional infos? Please contact us

hp-TECHNIK GmbH Industrial Pumps, Conveying units and plant construction