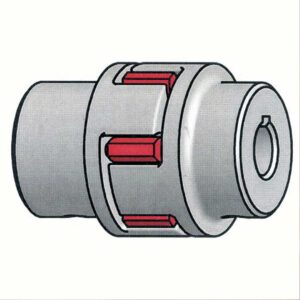

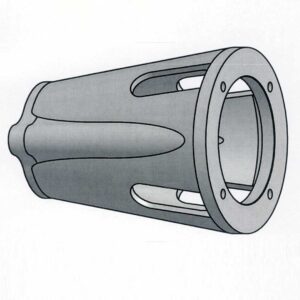

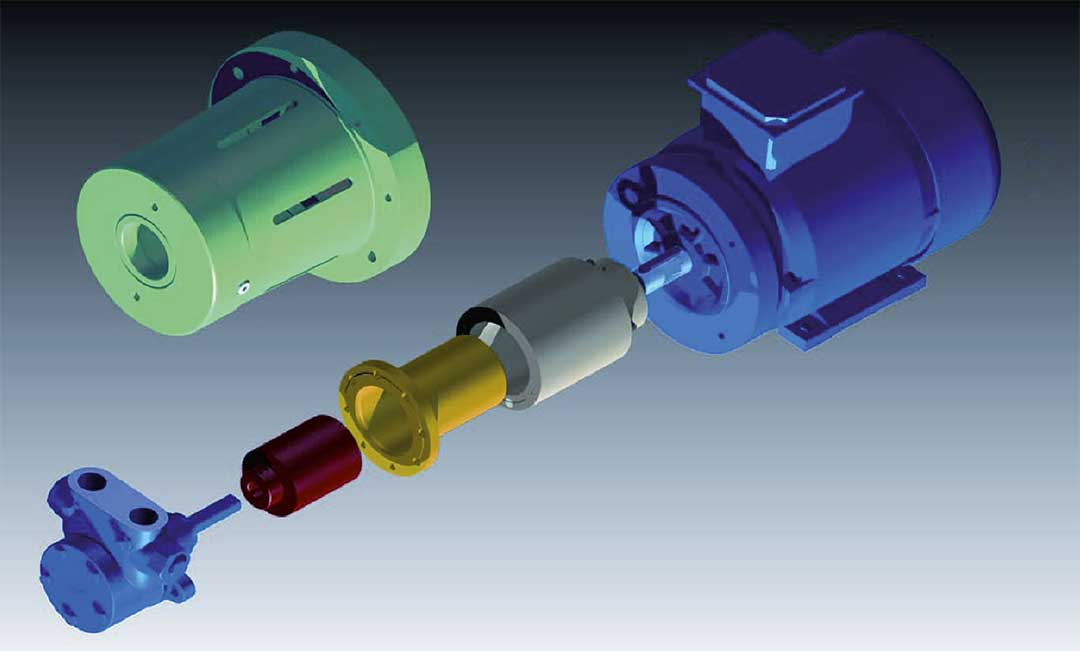

| Coupling PS/MS | Item No. |

| 12/11 | 820665 |

| 12/14 | 820666 |

| 12/19 | 820667 |

| 12/24 | 820668 |

| 18/19 | 820670 |

| 18/24 | 820671 |

| 18/28 | 820672 |

| 18/38 | 820674 |

| 22/24 | 820675 |

| 22/28 | 820676 |

| 22/38 | 820677 |

| Elastic crown gear for coupling PW 12 | 820669 |

| Elastic crown gear for coupling PW 18 | 820673 |

| Elastic crown gear for coupling PW 22 | 820678 |