Monarch offers a superior line of nozzles including the C-206 Air Operated Nozzles. This series is widely used on industrial burners using up to 30 psi air pressure for atomization. For excellent firing results use the C-206 in combination with high velocity combustion air.

C-206 nozzles are made of cold rolled steel and are precisely machined to combine aire and oil into a common swirl chamber through separate openings to properly proportion the two. This results in the oil being discharged in exceptionally fine spray ready for burning.

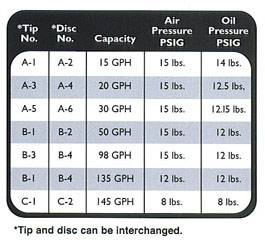

Flow ratings in the table are based on No. 2 fuel oil, but heavy oils can be handled satisfactorily provided they are preheated to bring the viscosity down to about 100 SSU. Flow rates shown are determined by air and oil pressures and turndown ratios between 3 and 4 to 1 can be obtained by reducing air pressure to as low as 5 psi, keeping oil pressure always tat least 2 psi higher than the air. Best atomization is obtained by regulation the air pressure. Some manufacturers operate at 15 psi constant air pressure and vary only the oil pressure for different flow rates and others modulate both air and oil pressures for maximum turn-down.

Minimum air requirement depends on oil pressures used, as any particular flow rate can be produced by an infinite number of different air-oil pressure combinations. Curve charts showing oil flow rates and air consumption at different air and oil pressures are available upon request for each size nozzle.

The C-206 nozzles come standard as a 60° spray angle but other specifications are available for custom requests.

ORDERING: Specify quantity and figure number

Note: Oil pressure must be at least 2 PSI higher than air pressure.

Refer to burner manufacturer’s instructions.

Need additional infos? Please contact us